Understanding the Uses of a Galvanometer Scanner in Precision Measurement Applications

Galvanometer scanners have become critical tools in accuracy measurement applications, specifically because of their remarkable capability to adjust laser beam of lights with exceptional rate and accuracy. This ability is crucial in numerous areas, consisting of production and biomedical imaging, where the accuracy of dimensions can straight influence outcomes. Understanding the operational technicians and diverse applications of these scanners exposes not only their importance but additionally the benefits they give in preserving market requirements. As we check out these aspects, the ramifications for future technical improvements and operational effectiveness necessitate cautious consideration.

Exactly How Galvanometer Scanners Work

A galvanometer scanner runs by using the concept of electromagnetic deflection to regulate the setting of a beam. This tool includes a coil suspended in an electromagnetic field, where electrical currents travelling through the coil develop a torque that triggers it to turn. The angle of deflection is proportional to the present, allowing exact control over the beam's position.

Usually, galvanometer scanners use a combination of mirrors and lenses to direct the light beam across a wanted surface or medium - galvanometer scanner. The rapid feedback time of the galvanometer enables high-speed scanning and exact placing, making it appropriate for numerous applications. The feedback system, frequently incorporated into the system, makes certain that the beam stays aligned with the intended target by readjusting the existing based upon the real deflection angle

The building materials and design of the galvanometer, consisting of the coil resistance and the toughness of the electromagnetic field, are crucial variables that influence its performance. These elements add to the scanner's level of sensitivity, resolution, and total functional performance. Understanding exactly how galvanometer scanners work is crucial for optimizing their use in accuracy dimension applications.

Applications in Laser Scanning

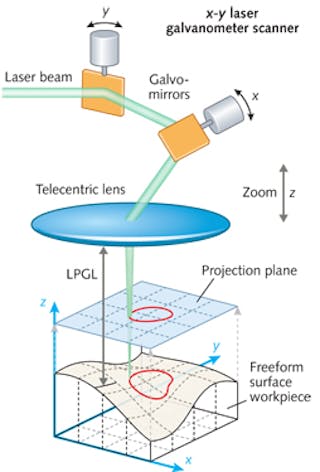

Galvanometer scanners play a vital role in laser scanning applications, where precision and speed are paramount. These devices utilize a rotating mirror system to guide laser beams with high precision throughout numerous surface areas, making them important in fields such as material processing, 3D scanning, and laser marking. The ability of galvanometer scanners to achieve quick angular movement enables efficient raster scanning, which is important for creating high-resolution and detailed images.

In industrial settings, galvanometer scanners are critical in laser cutting and inscription, where they supply regular and repeatable control over the laser beam's placement. This ability makes sure that complex designs can be carried out with minimal errors, boosting manufacturing high quality. In addition, in the world of 3D laser scanning, these scanners assist in the capture of complex geometries by rapidly brushing up the laser beam over a things, creating exact point clouds for electronic modeling.

In addition, the combination of galvanometer scanners in laser display modern technologies showcases their adaptability. They enable the production of vibrant visual results in home entertainment and advertising, more illustrating the relevance of accuracy in laser scanning applications across varied markets.

Role in Biomedical Imaging

Making use of galvanometer scanners in biomedical imaging dramatically improves the accuracy and speed of information procurement in numerous medical applications. These scanners facilitate quick and accurate positioning of laser light beams, which is important for high-resolution imaging strategies such as optical coherence tomography (OCT) and confocal microscopy. By utilizing galvanometer scanners, medical care experts can get comprehensive cross-sectional images of tissues, permitting for early diagnosis and reliable surveillance of diseases.

In addition to boosting picture high quality, galvanometer scanners add to the performance of imaging procedures. Their capability to rapidly and accurately straight laser light beams minimizes movement artefacts, boosting the reliability of the information collected. This is particularly vital in dynamic settings where person movement might compromise image integrity.

Additionally, the flexibility of galvanometer scanners to numerous wavelengths and imaging methods makes them important to innovative biomedical study. They can be used in fluorescence imaging, enabling researchers to study cellular processes and molecular interactions with extraordinary quality. As the area of biomedical imaging continues to progress, the role of galvanometer scanners will remain pivotal in driving advancements that enhance analysis capabilities and improve patient results.

Importance in Industrial Processes

Additionally, galvanometer scanners are necessary in optical examination systems, where they enable real-time tracking of manufacturing lines. By Look At This promptly scanning products for issues, these systems help preserve rigid quality assurance standards, guaranteeing that only items fulfilling specs continue to the following stage of production. Furthermore, in the world of 3D printing, galvanometer scanners add to the accuracy of layer deposition, substantially affecting the final product's precision and architectural honesty.

In markets such as electronic devices and auto, the capacity to carry out exact dimensions and modifications in real-time translates to boosted performance and productivity. The application of galvanometer scanners not only enhances operational abilities yet additionally plays a vital function in driving advancement across various commercial fields.

Advantages of Accuracy Measurement

Accuracy measurement is a keystone of modern industrial operations, providing various advantages that can significantly boost product high quality and operational effectiveness. By ensuring that dimensions are consistent and accurate, organizations can decrease irregularity in production processes, bring about more uniform items. This harmony not only fulfills customer expectations however also minimizes waste, as less malfunctioning items make it to the last phases of production.

Additionally, precision measurement promotes compliance with industry criteria and regulations. Precise dimensions are vital for meeting safety and high quality benchmarks, which can safeguard services from pricey penalties and reputational damage. The use of sophisticated dimension modern technologies, such as galvanometer scanners, makes it possible for rapid information procurement and evaluation, further improving procedures.

On top of that, precision measurement improves decision-making capabilities within organizations. By offering reliable data, it permits notified critical preparation and source appropriation. In an open market, these benefits find more information can cause raised productivity and market share.

Ultimately, the integration of precision dimension into industrial procedures is not simply an option; it is a necessity for businesses seeking to flourish in a progressively demanding setting. galvanometer scanner. The advantages extend past immediate gains, positioning firms for long-lasting success

Conclusion

To conclude, galvanometer scanners offer as important tools in precision measurement applications, enhancing the precision and speed of laser beam control throughout various sectors. Their combination into procedures such as laser cutting, noting, and biomedical imaging highlights their significance in boosting operational effectiveness and making sure conformity with sector requirements. The benefits provided by these scanners, consisting of decreased irregularity and enhanced data procurement, underscore their crucial function beforehand technology and cultivating technology in competitive markets.

Galvanometer scanners have arised as pivotal Learn More Here tools in accuracy measurement applications, especially due to their exceptional ability to control laser beams with extraordinary speed and accuracy.Galvanometer scanners play an essential duty in laser scanning applications, where accuracy and rate are paramount.In industrial settings, galvanometer scanners are instrumental in laser cutting and engraving, where they supply repeatable and regular control over the laser light beam's placement. In laser machining, galvanometer scanners direct laser beams with extraordinary accuracy, promoting intricate cutting, engraving, and marking jobs.In verdict, galvanometer scanners offer as crucial instruments in precision measurement applications, improving the precision and rate of laser light beam control throughout various industries.